The exceptional mixing and heat transfer abilities of such equipment assure uniform drying, therefore making sure quality and regularity. Simplicity in design and style can make fluidized bed dryers quick to work and preserve, that's why These are the popular choice for a myriad of industrial apps.

Sizeable tension drops are because of the requirement to suspend the complete bed in gas, resulting in superior Power utilization.

The impeller is intended at the bottom with the S.S. quality 316 dome-formed bowl. The impeller mixes the dry powder uniformly and prepares a wet mass following the addition of the binder. It is made up of two significant blades ( answerable for mixing the dispensed elements) and two tiny blades( chargeable for lifting the dispensed resources ) which might be operated at a decreased speed through binder addition. Then it operated at a pace of 200 rpm or as given in batch producing data.

This drags and condenses the drinking water Or moisture in the air and causes it to be dry. The chilled h2o piping (provide and return line), and also, the Regulate valve are beyond the AHU.

The producing of fluidized bed dryer filter bag depends upon required aspect like retention micron, static improve and air permeability. Fluidized bed dryer filter bags are Expense-effective and sturdy, as These are made according to the specification and so are consistently analyzed to satisfy regular high-quality.

And finally, fluidized bed dryers might be much less suited to supplies that have extensive particle measurement distributions; these can result in segregation in the mattress, the place smaller particles fluidize much more quickly, although more substantial ones keep on being mostly static.

If vendor has their own personal calculations readily available, we have to see and Examine them on our specs and requirements.

The FBD course of action is a greatly used method while in the pharmaceutical industry for drying and granulation. It offers many rewards, such as uniform drying, improved product or service high quality, and get more info minimized drying time. Appropriate Regulate and checking of system parameters, in addition to regular tools servicing, are important for achieving ideal brings about the FBD process.

As the hot air passes by container granules begin to suspend in the air to become dry (referred to as a fluidized point out), the procedure is termed fluidization.

When the gas or air velocity is elevated, it reaches some extent in which the drag drive exerted on the particles overcomes their body weight, producing them to be suspended during the fluidized mattress.

A fluidized bed dryer operates by passing Sizzling air with higher pressure via a perforated bed of moist solid particles. The new air passes at a velocity bigger compared to the settling velocity from the particles ensuing, particles starting to suspend during the air.

Drying is achieved at a relentless charge that has a residence time of about 30 to forty minutes. After the drying is done, the fabric check here is remaining from the dryer for quite a while to attain ambient room temperature.

The dryer is made up of chrome steel or plastic. A detachable bowl is positioned at the bottom on the dryer, that is useful for charging & discharging.

The underside with the fluidized-bed dryer is perforated, the place scorching air moves from the granules to become dried. The granules increase from The underside in the air stream as They are really suspended in it.

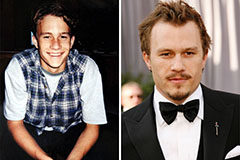

Heath Ledger Then & Now!

Heath Ledger Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!